What Is an Autoclave?

Autoclaves referred to as a steam sterilizer, they are essential tools in pharmaceutical microbiology laboratory and industrial environments. First developed in 1879 by French microbiologist Charles Chamberland, the autoclave offered a safer and more effective alternative to the old method of using open flames for sterilization.

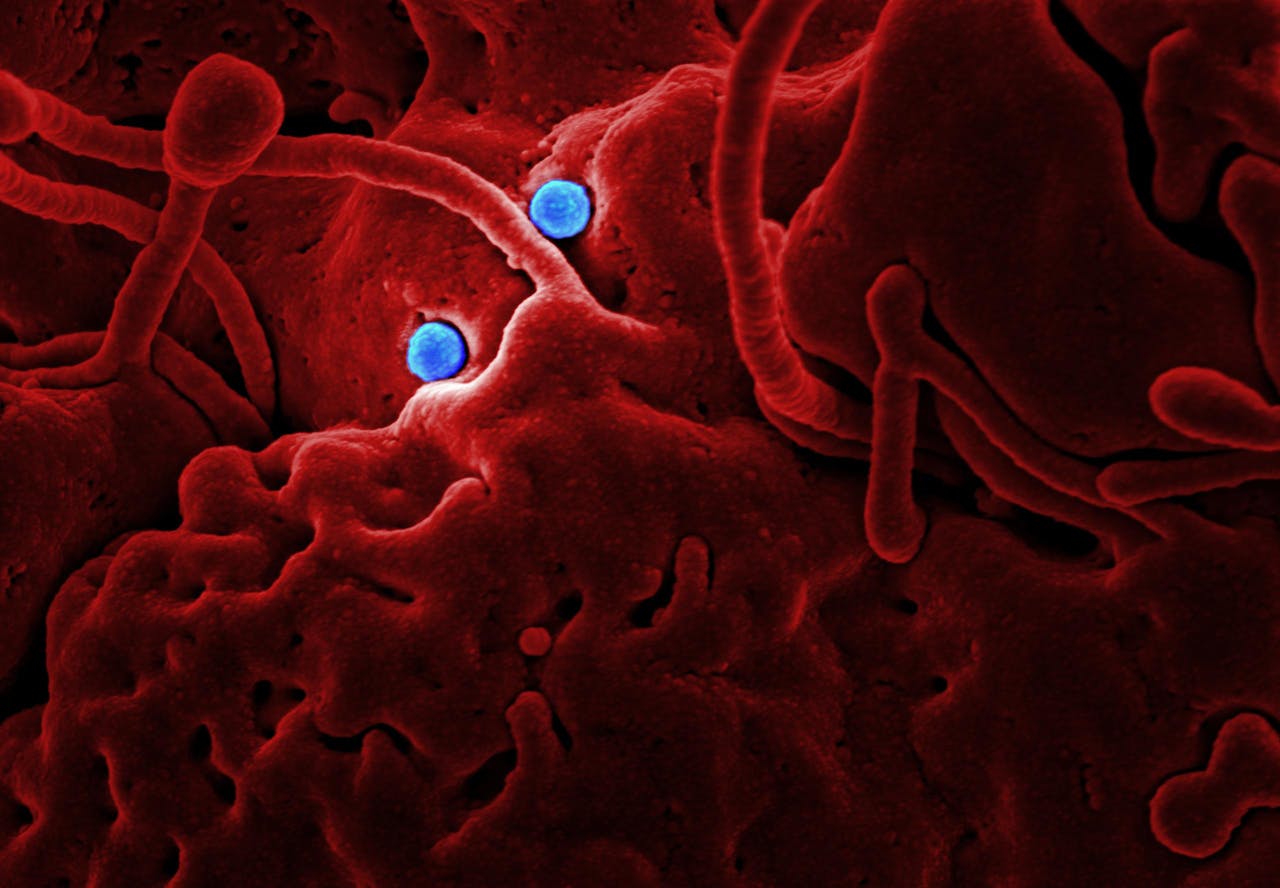

These machines use saturated steam to destroy harmful microbes, including bacteria and spores, which may survive traditional cleaning methods. Autoclaves come in various shapes and sizes, but they all operate on the same basic principle—steam under pressure using high temperature(121°C) and pressure(15Lbs) to ensure complete sterilization.

How Do Autoclaves Work?

You can think of an autoclave much like a pressure cooker. It creates a sealed environment where steam builds up under pressure, raising the temperature to levels that most microorganisms simply can’t survive. This makes autoclaving one of the most effective ways to sterilize tools, especially those with hard-to-reach crevices that detergents might miss.

As pressure increases inside the autoclave, so does the temperature. This intense combination helps the steam deeply penetrate materials and fully sterilize everything from surgical tools to lab instruments.

The word autoclave actually comes from two roots: “auto” (self) and “clave” (lock), reflecting the machine’s ability to automatically seal itself once the process begins. Even so, external locks are also used to add an extra layer of safety.

Types of Autoclaves

Autoclaves vary in size depending on their application:

vertical Autoclaves: it contains single door and easy to operate. mostly used for decontamination of microbiology waste.

Horizontal Autoclaves: Used in hospitals, these can process a high volume of equipment at once.it have a double door mostly used this for media and accessories sterilization purpose

Four important autoclave procedures you should know:

| Test/Cycle | Purpose | Frequency | Best For |

|---|---|---|---|

| Vacuum Leak Test | Checks for air leaks in the chamber | Daily | All autoclave loads |

| Bowie-Dick Test | Validates steam penetration & air removal | Daily | Pre-vacuum systems |

| Media Cycle | Sterilizes heat-sensitive lab media | As needed | Agar, broth, culture liquids |

| HPHV Cycle | Deep sterilization and drying | Routine | Surgical tools, textiles, tubing |

Do Not Autoclave:

Strong acids or bases

Flammable liquids

Materials like polyethylene, polystyrene, or polyurethane

These materials can melt, release toxic fumes, or even cause explosions under high pressure.

To ensure safe operation, autoclave users must be trained on what can and can’t go into the chamber—and how to run the machine properly.