This article discusses a number of pharmaceutical industries that have a clean rooms, controlled environments, and aseptic processing zones.Maintaining the validity of these controlled areas requires regular cleaning, disinfection, and sanitization.To avoid microbial contamination, they use 70% IPA.Generally, 70% IPA is one of the disinfectants that is most frequently used in the pharmaceutical industry.

Isopropyl alcohol (2-propanol), also called Isopropanol, or IPA, is a solvent that has been in use as a cleaning agent in several sectors, including hospitals and electronics, for several years. The IPA can act as a disinfectant effectively, however, there are some risks associated with the use of IPA if reacted ineffectively; some may be fatal. Continue reading to know the reasons why there is a need to use isopropyl alcohol and also how to make use of it appropriately. For more specific information Regarding the concentration of IPA, see the article about the need for a quality USP IPA. To further understand the broad applications of IPA and why it is necessary to use the correct type of ISP for various cleaning procedures, see ISP as a universal cleaner.

As the name implies, pure isopropyl alcohol is produced and handled in a way that contains no additives, which makes it non-consumable by humans. Such type evaporates quickly and is non-staining. Pure isopropyl alcohol is more dissimilar and distinguished from sterile or single use as usp grade isopropyl alcohol.

USP-Grade IPA:

The usp certification indicates that your product has undergone processing, which is the key in manufacturing, packaging, storing and inspection of your goods. It has enhanced the safety and effectiveness of the product for any use.

Sterile IPA:

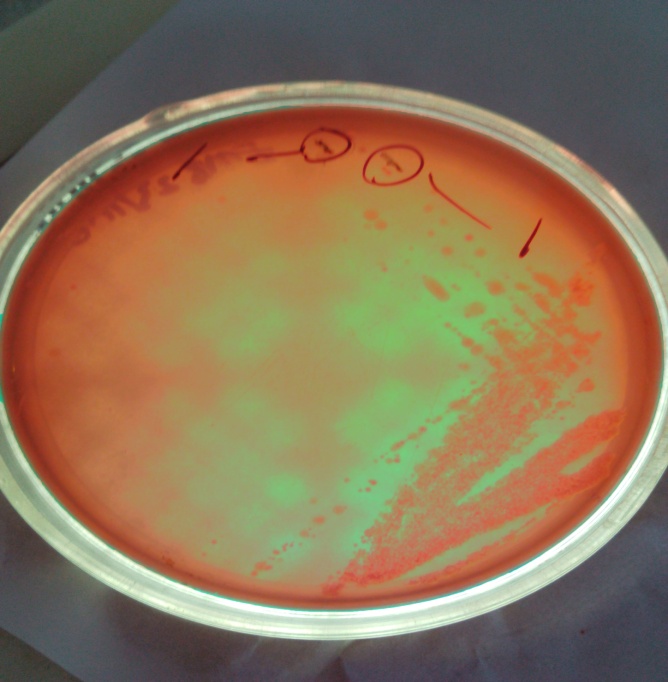

Sterile Isopropyl Alcohol is a solution containing isopropyl alcohol, which was developed specifically for use in clean rooms regardless of the most stringent purity. To maintain sterility, it has been subject to Sub-micron filteration, put in sterile washed containers, double blister packed and gamma irradiation (generally done in sterile cleanrooms). The most popular application of such kind of alcohol is a complete disinfection of cleanroom furniture.

Food-Grade Alcohol:

Very few commodities contain isopropyl alcohol in its manufacture, which are safe for consumption.

You might find isopropyl alcohol present in some food flavoring enhancers, perfumes, fats, oils, dyes, chemical preservatives, sweeteners, and even some probiotics.

Food grade products can generally be presumed to contain ethyl alcohol, as that is safe. An ingredient is described as the active ingredient in a drug product; therefore, known components of quality systems that the FDA incorporates are straightforward: those ensuring products to be consumed by humans are of quality to be maintained https://modrenmicrobiology.site/the-challenge-of-isolating-e-coli-and-salmonella-from-sewers/

Anhydrous Alcohol:

A solvent that does not contain any water is referred to as anhydrous. However, anyway, a 100% isopropyl alcohol solvent is pointless for manufacturing intentionally, as it shall absorb any amount of water vapor present in the atmosphere. Alcohols that are labeled as anhydrous alcohols of high-quality produce purity more than 99.96 %.

NSF-Grade IPA:

The other organization working and committed to bettering health worldwide is the National Sanitation Foundation (NSF). NSF is a nonprofit organization whose activities perform charitable purposes. If the product bears the big NSF seal, it means that the product has been tested at every stage of production and manufacturing, with all the requirements clearly met. This involves food industries, water supply, consumer products, as well as the environment where human beings live. Apart from putting the products through rigorous testing, NSF also conducts physical inspections of the manufacturing plants. The organization, which is dedicated to the cause of public health, however issues remedial measures like product recalls, public alerts about products or even deregistration of products against companies or products that fail to meet their standards.

Industrial-grade IPA:

Industrial-grade isopropyl alcohol, or technical-grade isopropyl alcohol, finds most of its applications in non-critical manufacturing and processing work.

Cost-effective industrial-grade isopropyl alcohol is available for cleaning of wider surfaces.

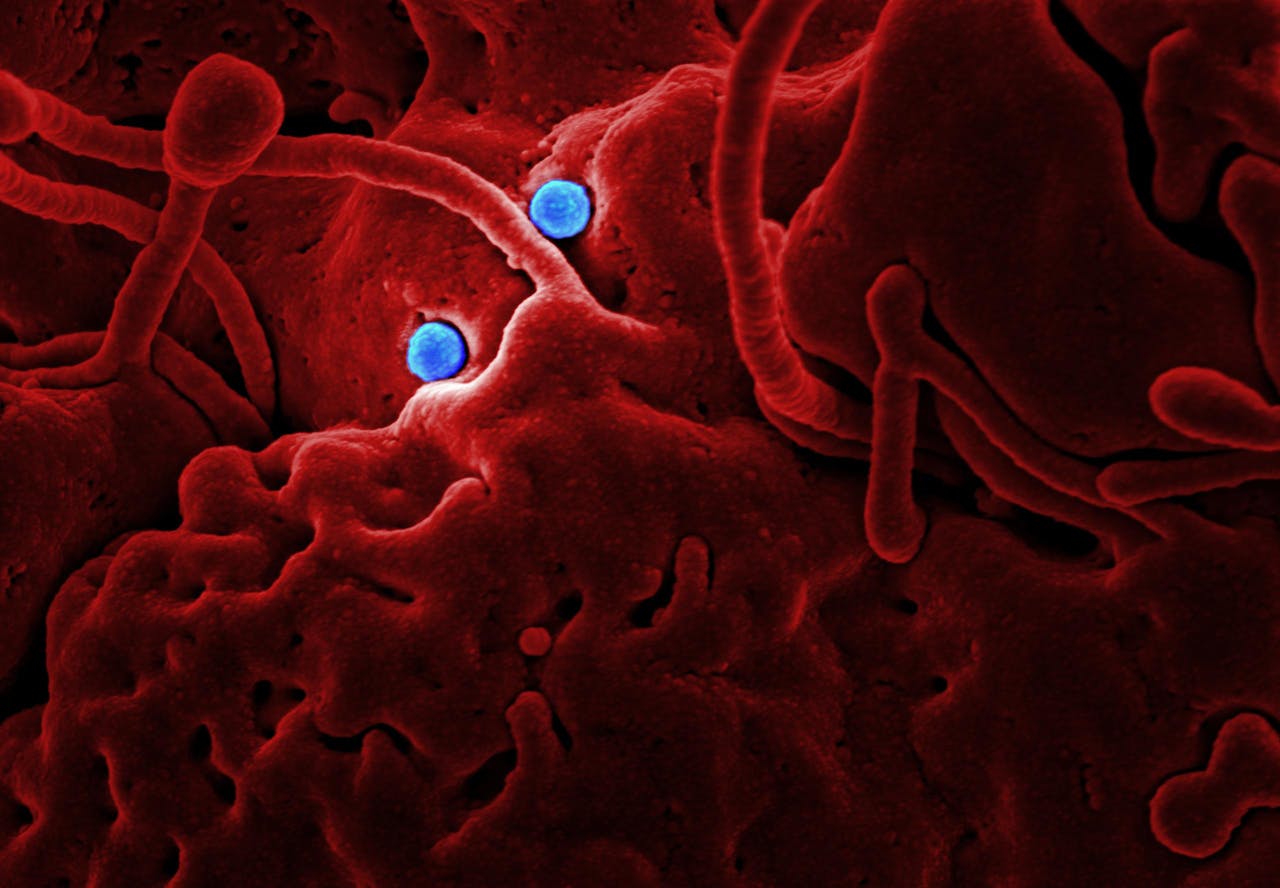

Denaturation of proteins:

Isopropyl alcohol kills microbes because of its property of denaturing proteins. It has 70% solution that has enough water that the rate of evaporation cannot get too high, and the alcohol molecules may penetrate well through the microbial cell walls in which proteins can be denatured over a longer period.More time in evaporation: Solutions that are 90% or 100% evaporate too fast. It would reduce the contact time of the disinfectant with the microorganisms, thereby less effective for the disinfectant.

Water as a catalyst:

Water is essential in the sense that it is through water that alcohol penetrates the cells of the microorganism.

Water increases alcohol absorption into cells, and this results in great coagulation of proteins, thus allowing more effective killing of microorganisms.

This particular 70% IPA is strong enough to eradicate most of the bacteria, viruses, and fungi. Because of this reason, it is utilized as a general disinfectant.

70% isopropyl alcohol can be very useful for use in clean rooms, hospitals, and for medical device manufacturing and can be safely used for general-purpose cleaning as well-known disinfectant.

The 70% IPA/30% water solutions are less prone to burning than an IPA solution over 70%.Isopropyl alcohol, once exposed to air, light, and oxygen, is eventually consumed in producing unstable peroxides.

This will increase the chances of a fire; the longer it is kept, the higher the possibility of an explosion.

Observe how old your isopropyl alcohol solution is. If it is older than three years, it is probably best avoided, particularly if it has been open for several years and has been exposed to air and light.

70% IPA is less likely to cause adverse health reactions than over 70% isopropyl alcohol solutions and is also cheaper for general use and large cleaning jobs. With more water in the solution, the disinfectant will evaporate more slowly. This means more powerful cleaning as the amount of time that the cleaning agent is actually on the surface is extended. With all of the above merits, 70% IPA is better than a higher concentration of IPA.